Chazan-McGovern

Chazan, M. & P. McGovern. "Khirbet Kerak

Pottery at Beth Shan: Technological Evidence for Local Manufacture" in

MASCA Journal 3.1 (1984), pp. 20-24.

Introduction

Khirbet Kerak

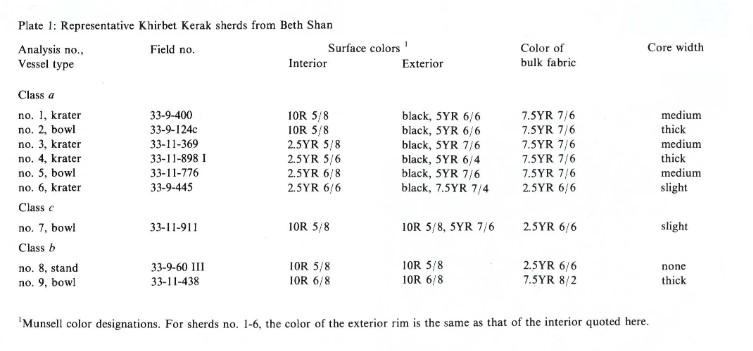

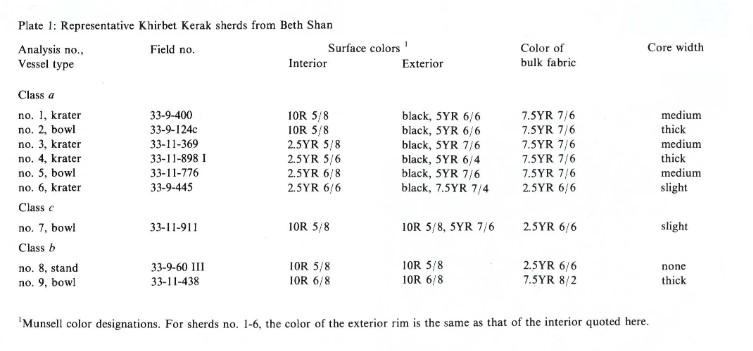

pottery, first identified by Albright (1926) at the Palestinian site of that name, is a highly distinctive class of ceramics. Its hallmark is an intense red/black surface contrast (Plate l). It first appeared in northern

Palestine at the beginning of Early Bronze III (

circa 2750 B.C.), and continued in use until the end of that period (

circa 2300 B.C.), at which time it disappeared. Besides northern

Palestine, quantities of this

pottery have been found in certain other regions of the Near East (eastern Anatolia/Transcaucasia and the 'Amuq), but intervening and otherwise accessible areas (southern Anatolia the Levantine coast, southern

Palestine,

etc.) have yielded very little. To many scholars this peculiar geographic distribution suggested invasion and/or mass migrations from eastern Anatolia and Transcaucasia where there appeared to be antecedent ceramic traditions (Hood 1951, Woolley 1968

Amiran 1968). However, as the chronology and somewhat divergent repertoires of the various regions have come to be better understood (

Lamb 1954, Mellaart 1966, Todd 1973), a more cautious approach has developed.

One alternative hypothesis is that itinerant potters from eastern Anatolia/Transcaucasia may have travelled between and even settled in, prominent towns of the 'Amuq and northern

Palestine (Hennessy 1967). Such a hypothesis might better explain how local

pottery types (e.g. the one-handled Palestinian jug) came to be decorated in Khirbet Kerak fashion since invaders or migrants would not have been inclined to adopt local styles. As a corollary, regional technological differences would also be expected as the foreign potters adapted themselves to the local ceramic industry. As a first step in testing this hypothesis, a pilot technical study was under taken on Khirbet Kerak

pottery from Beth Shan, under the assumption that this group is representative of one of the three principal regions (viz., northern

Palestine) for the pottery's production

.Characterization of wares

The Beth Shan corpus comprised more than a hundred sherds but it could be divided readily into

just four groups according to surface finish.

a. Lustrous red and black. the 'classic' decoration. Bowls and kraters usually have a hand-burnished red interior, continuing over the rim where a narrow, irregular reddish yellow band merges with

the exterior black burnished surface (Plate l sherds I-6). Jugs and tall

stands are sometimes similarly decorated.

b. Lustrous overall red or black. Less often. bowls have a completely red or black burnished surface (Plate l: sherd 9) Stands and jugs are most often decorated red in this fashion

(Plate l: sherd 8) Low relief plastic designs (chevrons, diagonal ribbing, elc.) also occur on the first two classes of bowls and kraters.

c., Red painted. Very rarely, bowls and jugs have red painted geometrical designs (triangles, circles, crisscrosses, etc.) over a brown body surface (Plate l: sherd 7). The red paint is

burnished to a high gloss in reserve fashion so as to contrast with the unburnished background. On stands and "fenders (horse-shoe shaped objects), this decoration is sometimes

combined with geometric and abstract figural designs.

d. Unburnished brown or gray. This surface decoration is found almost exclusively on fenders and conical lids

Seven representative burnished sherds were selected for study: three bowls and one

krater from Class a, two stands from Class b (red), and one

bowl from Class c. Each was sectioned perpendicular to its horizontal plane with a non-deformational diamond saw (Buehler Isomer). Additional tile-shaped pieces were cut from one of the kraters (Plate 1: sherd I), in order to carry out refining analyses at 500, 750, 850, 950, and l 000"C respectively. A servo-controlled Lindberg muffle furnace allowed attainment of the peak temperature (fluctuation, i'5"C maximum) within 20 minutes, and a prolonged stable heating of the tile in an oxidizing atmosphere for another hour after that.

All samples, retired and unrefined, were then graphite or gold-palladium coated for SEM examination, with magnifications typically in the 300X to l 000X range. It was then possible to establish (I) presence/absence of a slip or paint, and (2) the extent of the glassy phase (vitrification) which relates to the temperature and duration of firing. An EDS attached to the SEM provided semi-quantitative chemical analyses of slip/paint (when present) and of the body ware.

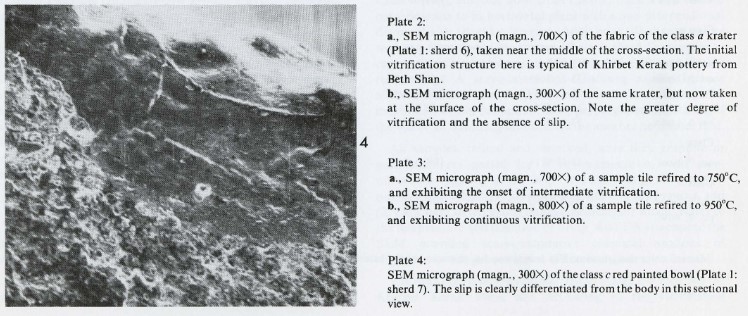

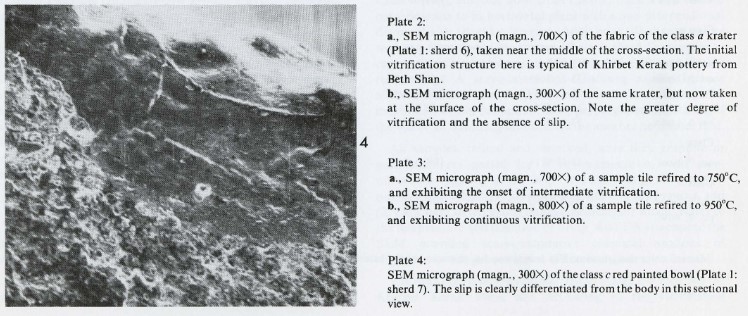

The data obtained are summarized in Plates 2-4 here. All the Khirbet Kerak wares are, according to the vitrification

distinctions developed by Tite

et al. (l982a), only in the initial stage of vitrification, i.e., uniformly low fired. Most sherds do, however, exhibit an intermediate stage of vitrification near their surfaces (of Plates 2a,b). Of the retired tiles, the one held at 500°C had an interior vitrification structure that was almost identical to its unrefined counterpart, while the tile fired to 750°C had a body structure that was closest to the intermediate stage of fusion near the surface of the original specimen (Plate 3a). By 950°C a continuously vitrified

fabric with bloating pores (up to 20 microns in

diameter) had developed (Plate 3b).

All the wares were made of a calcareous clay (Ca,

circa 5- l0%), and marked changes in color and structural integrity with refining were typified by one of the Class a kraters (Plate 1: sherd I, and Table l). A separate layer of clay had been

applied as a slip to achieve a deeper hued red (10R 5-6/8, 2.5YR 5/6-8) on sherds 1-4 and 7-9 (Plate l). That layer (of thickness ranging 10 to 100 microns) could be clearly differentiated by its finer particles, greater vitrification, and non-calcareous composition (Ca

unslipped surface that is used instead of a deeper red slip on two Class a pieces (Plate l: sherds 5 and 6).

Interpretation

The very limited use of slips at Beth Shan conflicts with previous descriptions of Khirbet Kerak pottery (see Albright 1926; FitzGerald 1934; Hood 1951; Mellaart 1966; Amiran 1970; Kenyon 1979). Matson (1960)and Hennessy (1967) imply that, while slipped Khirbet Kerak wares were the norm, comparable unslipped vessels were sometimes produced. Beth Shan would appear to fall at the opposite end of the spectrum compared to most sites where the pottery has been found, i.e., color variations were often achieved here on an unslipped rather than on a slipped surface.

The instances of an intense red slip demonstrate however that slipping was still part of the ceramic tradition at Beth Shan. Except fore lower calcium content, the slip is chemically similar to the body fabric, which suggests that it is a finely levigated fraction of the same clay. The advantages of using a non-calcareous slip on a calcareous body, which was part of the Near Eastern potter's craft from at least Chalcolithic times up until the Roman period, were several: a more closely-packed structure capable of sintering at lower temperatures, a thermal expansion coefficient similar to that of the underlying body (so that the possibility of crazing is decreased), and a greater color contrast between the slip and the lighter colored calcareous ware (Tite et al. 1982b). Slips also offered the potter a ready means for producing complex surface decoration.

An original firing temperature in the 500-750°C range is also in accord with previous work on Near Eastern calcareous wares (Tite el al. l 982b). Intermediate vitrification near some of the surfaces is most likely explained by transient temperature gradients.

The low firing range points to the use of a bonfire or a clamp. Actual firing installations for Khirbet Kerak pottery have not yet been excavated, but kilns would normally have been fired to higher temperatures-800 to l 000°C (Mayes 1961, 1962; Bryant 1970, 1978).

The assumption of an open pit firing also helps to explain a peculiarity of most of the red and black lustrous examples. In section the black core is seen to extend up to a point opposite the change from red to reddish yellow on the exterior surface rather than being further down where the reddish yellow changes to black (e.g., Plate 1: sherd 5). This can be explained by assuming that, while the interior of the vessel and the exterior rim were exposed to air throughout firing, the remainder of the exterior was in a reducing atmosphere until just near the end of the firing. Then an upper, irregular portion of the black surface was reoxidized to reddish yellow, comparable with the color of the body fabric. This reoxidation must have been of short duration and/or at a low temperature, since the reddish yellow does not penetrate the black core to any great extent (typically, less than 100 microns).

Such an effect could have been achieved in an open pit firing by packing organic material and fuel around the vessel, thus smoking and cutting off oxygen to its exterior (Noll l 977; Lucas 1962). By the end of the firing, some of the packing may have burned away or been pushed aside by the potter, so that the upper black surface was exposed to the air. Lack of control in firing (rapid fuel consumption, high temperatures) would also contribute to an occasional exterior spot oxidation and sometimes total oxidation from the inside out (Plate l: sherd 6). Other scenarios are possible-pressing a red-hot vessel into an organic medium (Lucas l 962) or immersing it in hot oil (Matson l 960)-but they do not account for the facts as well. Smoke blackening over a cooking fire (Yadin I 947) could hardly have been well controlled or intense enough to have produced such uniform black surface coloration and the thick cores that merge with the surface.

We have not yet determined the chemical species responsible for the black coloration, but the ferrous spinet phases (principally hercynite and magnetite: see Noll et al. 1975, Maggetti et al. 1981, Hofmann 1962, 1966, Longworth and Tite I 979) and/or elemental carbon (Gillies and Urch 1983) are the most likely possibilities. The Beth Shan wares here have a relatively high iron content (circa 5%-10% as hematite) that is presumably responsible for the intense reds. However, for black coloration, amorphous carbon might well have played a more significant role than ferrous compounds, if the external reducing environment was indeed achieved by surrounding the pottery with organic packing. The relative ease with which the black surfaces are reoxidized to the body fabric color, which would be inhibited by ferrous spinets (Tite et al. l982a) supports this assumption. Carbon content could be enhanced yet further by the use of a carbonaceous clay, or by the addition of organic matter to the clay.

A high level of technological proficiency is attested to in the Beth Shan corpus of Khirbet Kerak pottery. High temperature kiln firings are not needed to explain its notable aesthetic features. Rather, careful control of the oxidizing/reducing atmosphere at low temperatures appears to have been most critical.

The sheen of the lustrous Khirbet Kerak pottery was accomplished by very careful hand-burnishing of the entire surface, which pushed the larger inclusions below the surface and aligned particles parallel to the surface. The glossy appearance thus achieved is remarkably similar to modern Pueblo pottery made by Martina Martinez. Although Martinez uses a slip, she emphasizes the burnishing: "Still it is our long hard polish...we work very hard...that makes ours so pretty (Peterson 1977). The Pueblo pottery is also made black by carefully smothering and smoking an open fire around the vessels.

It remains to be seen whether the limited use of slips to produce the characteristic visual appearance of Khirbet Kerak pottery is a localized technological variant at Beth Shan or a more common method of surface treatment elsewhere Together with chemical and petrographic provenancing (e.g McGovern ez al. 1982), detailed study of Khirbet Kerak pottery from sites in the other principal areas is needed to resolve this question.

Acknowledgments

This study is affectionately dedicated to the memory of Dr. Frances W. James. We would like to thank Prof. M.R. Notis and Ms. H. Moyer for their assistance with the SEM studies which were undertaken at Lehigh University.

References

Albright, W.F., 1926: Ann. of the American Schools of Oriental Research 6, 13.

Amiran, R., 1952: Israel Exploration Journal 2, 89.

Amiran. R., 1968: Amer. Journ. of Archaeology 72, 316.

Amiran, R., 1970: Ancient Pottery of the Holy Land (Rutgers University, New Brunswick).

Braidwood. R.J., Braidwood. L.S., 1960: Excavations in the Plain of Antioch I (Oriental Inst. Publ. 61, University of Chicago, Chicago).

Bryant, G.F., 1970: Journ. of the Scunthorpe Museum Society

Bryant, G.F., 1978: Acta Praehistorica ez Archaeologica 9/10, 13.

FitzGerald, G.M., 1934: Palestine Exploration Fund Quarterly Statement, 123.

FitzGerald. G.M,. 1935: The Museum Journal 24, 5.

Gillies, K.J.S., Urch, D.S., 1983: Archaeometry 25, 29.

Hennessy, J.B., 1967: The Foreign Relations of Palestine during the Early Bronze Age (Colt Archaeol. Inst. Publ., B Quaritch, London).

Hofmann, U., 1962: Angewandte Chemie (Intern. Ed.) 1, 341.

Hofmann, U., 1966: Naturwissenschaften 53, 218.

Hood. S., 1951: Anatolian Studies I. 1, 13.

Kenyon, K.M., 1979: Archaeology in the Holy Land (E. Benn London).

Lamb. W., 1954: Anatolian Studies 4. 21

Longworth, G., Tite, M.S., 1979: Journal de Physique 40, C2, 460.

Lucas, A., 1962: Ancient Egyptian Materials and Industries (E Arnold, London).

Maggetti, M., Galetti, G., Schwander, H., Picon, M. Wessicken, R., 1981: Archaeometry 23, 199.

McGovern. P.E. Harbottle. G.. Wnuk. C., 1982: MASCA Journal 2, 8.

Matson. F.R., 1960. 358. 398 in Braidwood, R.J., Braidwood, L.S. 1960, 358, 398.

Mayes, P., 1961: Archaeometry 4, 4.

Mayes, P., 1962: Archaeometry 5, 80.

Mellaart, J., 1966: The Chalcolithic and Early Bronze Ages in the Near East and Anatolia (Khayats, Beirut)

Noll, W., 1977: Archaeologie und Naturwissensehaften 1, 1

Noll, W., Holm, R., Born, L., 1975: Angewandte Chemie (Intern. Ed.) 14, 602

Peterson, S., 1977: The Living Tradition of Maria Martinez (Kodansha, Tokyo).

Tite, M.S., Maniatis, Y., Meeks, N.D., Bimson, M., Hughes MJ., Leppard, S.C., 1982a: in Early Pyrotechnology, 61 (Eds T.A. Wertime. S.F. Wertime. Smithsonian Institution Washington, D.C.).

Tite, M.S., Freestone. I.C., Meeks. N.D., Bimson. M., 1982b: in Archaeological Ceramics, 109 (Eds. J.S. Olin and A.D. Franklin, Smithsonian Institution, Washington D.C.)

Todd, I.A., 1973: in Orient and Occident. Alter Orient und Altos Testament 22, 181 (Ed. H.A. Hoff fer, Butzon and Bercker, Kevelaer).

Woolley, C.L., 1968: A Forgotten Kingdom (Norton, New York)

Yadin (Sukenik), Y., 1947: Bull. of the Amer. Schools of Oriental Research, 106, 9.

*The site of Beth Shan, which was excavated by the University Museum between 1921 and 1934, is strategically located at the juncture of the Jezreel and Jordan Valleys where major trade routes crossed between Egypt, Syria, and Jordan. Khirbet Kerak pottery was found together with Early Bronze III pottery exclusively in Levels XB through Xll at Beth Shan (FitzGerald 1934, 1935), sometimes in mixed EB IV and Middle Bronze contexts. However. the ceramic is so distinctive that macroscopic criteria (Amiran 1952, 1970, Braidwood and Braidwood 1960) are sufficient for its identification. The Beth Shan analytical program as been carried out in conjunction with Frances James reworking of the excavation data.

**Partly published in FitzGerald 1935. The collection was about evenly divided between the University Museum and the Rockefeller Museum in Jerusalem. Only the Philadelphia corpus is considered here.